FOR MORE THAN FIFTY YEARS, co-design and mechanical processing of steel, ferrous and nonferrous materials, aluminum alloys, titanium and noble plastic materials for small and medium high-precision components.

- Fifty-year experience in high-tech markets.

- Prototype Dept.

- Assembling & Testing Dept.

- Small and large series production.

- ISO 9001-2008 Quality System.

- Export sales to 18 countries.

- Consignment & KANBAN supply.

- Lean Manufacturing.

- R&D Dept. to support our customers.

- Specialized in processing ferrous materials, aluminum alloys, plastic materials.

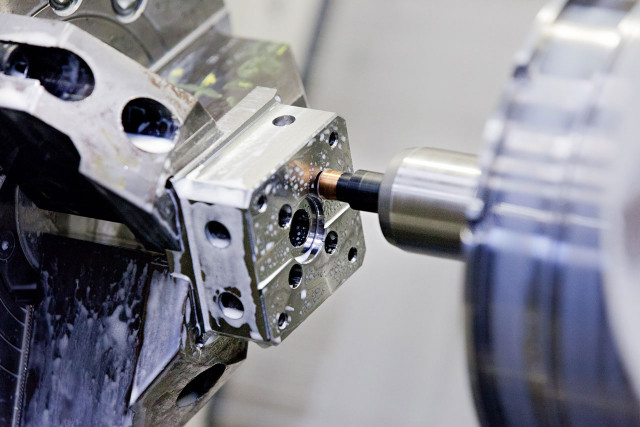

- CNC machines from 5 to 10-axis with FMS 24/7 production.

THE COMPANY

VEGA has proved to be able to satisfy a qualified national, European and international customer base, which appreciates the precision in every way.

The company offers its real expertise, which has been gained in more than fifty years of CNC manufacturing and assembling of both single parts, groups of parts, finished and tested assemblies, where the quality is a top-priority value from the beginning.

THE KEY TO SUCCESS

High quality, timeliness and innovation are the keys to the success of VEGA.

These results are achievable thanks to the technical know-how of the Management team, as well as the constant investments in new technologies, which provide the company with an excellent machinery inventory.

The experience gained in the mechanical manufacturing of various materials (steel, stainless steel, titanium, aluminum, copper, special alloys and plastic materials) gives VEGA the capability to deal with the most complex projects, complying with tight specifications for better Customer’s results.

The high manufacturing flexibility, the qualified personnel and the organizational efficiency represent an additional strength of the company.

All of the production is planned and carried out within the company, using cutting-edge technologies.

The heat treatments and surface finishes are committed to reliable, well-selected partners, who share with VEGA the same attention for the detail.

A PARTNER FOR THE DEVELOPMENT OF COMPLEX PROJECTS

The human and technological resources specifically dedicated to the design and prototyping allow VEGA to be a reliable partner, who is capable of contributing to the co-design of complex components.

This is possible sharing the same goal of the Customer, through the continuous search for the optimization of the processes and production technologies, as a guarantee of the effectiveness of the industrialization.

All of this gives VEGA the possibility to support the Customer, who is looking for a global industrial partner, going beyond the limits of the traditional supplier/Customer relationship.

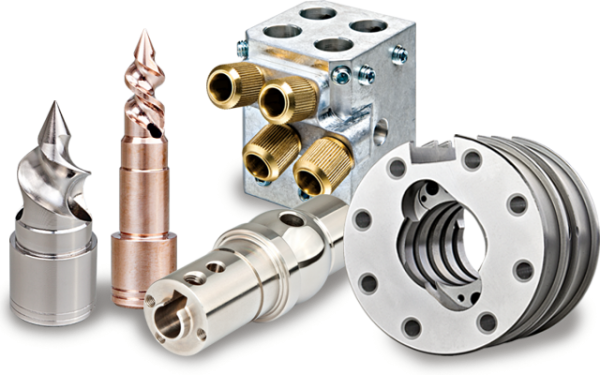

Fine Mechanic Works for small and medium sized components

The core business of VEGA is the manufacturing of small and medium mechanical components – the production batches can vary from the single prototype to several thousands of units. Given the types of industries, the medium volume of our production batches goes from 50 to 5,000 units per year.

The core of our expertise lies in the deep knowledge of the manufacturing processes of metals and plastic materials along with a passionate use of the most sophisticated technologies and CNC machines, where every day thousands of components materialize and then they are incorporated into their complex assemblies.

In addition to the traditional machines, the experts in VEGA program and equip some of the most sophisticated CNC machines on the market today. From 5-axis to multi-pallet horizontal machining centers, from multi-tasking turning machines to 10-axis sliding headstock turning machines.