People dedicated to customers

Supplied countries

Company History at a Glance

THE ORIGIN OF VEGA

THE ORIGIN OF VEGA

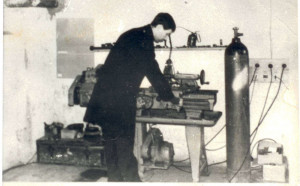

Alberto Vedovello and Giorgio Gabellini opened a production workshop for the maintenance and reparation of welding machineries. The name VEGA came from the initials of the last names Vedovello and Gabellini.

VEGA’s pivotal moment arrived as it secured its first contracts with medical testing device companies. This marked the start of VEGA’s expertise in diverse material manufacturing (Plexiglas, Teflon, Brass, AISI 316, Titanium, etc.), setting the stage for its future success.

In response to increasing demand for new applications and enhanced manufacturing capabilities, VEGA acquired its first two CNC machines. The Maho MH 500 C milling machine, featuring a movable pallet and manual tool change, and the Gildemeister GD200 lathe, equipped with an -station tool tower, ushered in a new era of ongoing investments that would have never stopped and still represents one of VEGA’s flagships.

VEGA reached technological maturity, driven by a growing customer base and the need for higher quality and productivity.

The company made a significant investment plan in machinery and human resources and found in MAZAK a key technological partner.

VEGA successfully expanded its customer base to include industries such as automation, textiles, laser machinery, aerospace, and molding.

In 1997, VEGA achieved its first ISO 9000 certification that marked the beginning of a new organizational phase, ensuring that VEGA’s customers would benefit from four key pillars: Quality, On-time Delivery, Competitive Pricing, and Pre- and Post-process Customer Support. VEGA also made significant strides by relocating to the headquarters in Scanzorosciate, a modern complex expanded in 2004 to 3,000m2, which included assembly and testing facilities as well as warehousing for raw materials and finished products.

In response to growing North American market demand, VEGA established a warehouse in Massachusetts, USA, storing components and finished products under ‘consignment’ or ‘kanban’ supply agreements. VEGA managed the entire process, including export, transportation, customs clearance, storage, and final delivery to the customer.

In 2007, VEGA introduced TECHNOFRAMES as a brand aimed at diversifying the production and offering a product line that includes Ammo Boxes, Showcases, Ammunition Replicas, and innovative Domotic Displays.

VEGA, under the TECHNOFRAMES brand, actively participated in numerous international trade fairs, establishing valuable connections with key players in the Firearm Industry. These engagements paved the way for significant technological and organizational advancements.

In 2017, VEGA made a substantial investment in TOYODA machinery to manufacture high-tech firearm parts, but also adaptable for different components. The company implemented the ‘Z-Production’ management system, which optimizes production by monitoring progress, managing resources, calculating production costs, controlling margins, and analyzing departmental performance.

In 2021, VEGA took a significant leap forward by relocating its headquarters to a larger facility in Grassobbio and revamping its production workshop. This move, coupled with the implementation of the new Z-Production system, enabled the company to streamline its production, ensuring faster order fulfillment and higher quality standards.

VEGA strengthened its commercial partnerships with customers, establishing framework agreements to ensure consistent production. The know-how gained in the Defense Industry presents potential opportunities for future development across other industries.